Rice and sake

Making one variety of sake, ginjo-shu, is considered to be the ultimate test of a brewer. It was made by brewers as a way of honing their skills. This type of sake has been on the market for only about ten years. Before, it was a kind of secret which was unavailable to anyone outside the trade. And this kind of sake is very special because it is one of the sakes we drink chill. Before, everybody had to heat sake from 36�C to 55�C, approximately...

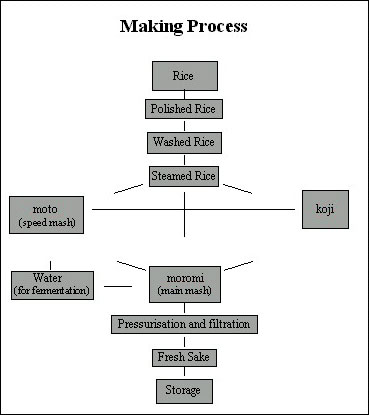

Making one variety of sake, ginjo-shu, is considered to be the ultimate test of a brewer. It was made by brewers as a way of honing their skills. This type of sake has been on the market for only about ten years. Before, it was a kind of secret which was unavailable to anyone outside the trade. And this kind of sake is very special because it is one of the sakes we drink chill. Before, everybody had to heat sake from 36�C to 55�C, approximately...Rice that will be made into sake is polished, then left to sit for about a month. It is then washed, and set aside for another day. Next, it is steamed. Then, it is cooled to the appropriate temperature for the koji yeast, which will be used to ferment the mixture to produce an unpressed sake called moromi (main mash). Cooling in frigid air is said to produce the best sake. That's why, an excellent and well-known variety, called kan-zukuri, is brewed during winter.

The next step is to sprinkle koji yeast on the steamed rice. In traditional sake making, this process lasts for two days and nights. During this time, workers have practically no time to eat and sleep.

Next comes the time of the moto. This step is indispensable to making a pure yeast. The yeast is then mixed with water, steamed rice, and koji to allow the yeast cells to convert the rice starch into sugar. The action of the yeast produces alcohol, and the resulting moromi becomes unpressed sake. This process takes twenty to thirty days for ordinary sake, although for daiginjo-shu sake the moromi will be left to ferment for 35 to 45 days.

Finally, the moromi is pressed to remove the sake lees. The resulting liquid is then filtered to produce pure sake. Products other than the pure sake are sterilised by heating gently at about 60�C, then allowed to mature in storage.

These days, the brewing process is mechanised and is done all year round. However, some brewers keep producing sake in the traditional manner, at the most suitable time of the year.

In traditional sake making, the chief brewer in charge of this process, called the toji, is like an orchestra conductor�: he must have a complete understanding of the various processes involved, and must be able to guide his workers, showing them how to obtain the perfect balance between flavour and aroma. There is also an old Japanese proverb which illustrates this�and the importance of working together: Teamwork makes good sake.

It is also generally said that quality of the sake depends on the purity of the water. In fact, the exquisitely delicate yet pronounced taste of sake is the product of clear water, bountiful nature, and years of technical experience, not to mention the affection with which Japanese people regard rice...